No Products in the Cart

Waiting for concrete to cure before evaluating its accuracy and quality has been a time-consuming and costly process in the construction industry. Traditional methods of assessing floor flatness and levelness required several hours, or even days, to perform measurements and analyze the data. However, with the advent of innovative technology, such as the FARO Flatness Check, the entire process can now be reduced to minutes. In this blog post, we will explore how the FARO Flatness Check, an augmented reality application compatible with iOS devices, revolutionizes concrete quality control, improves efficiency, and reduces rework.

Same-Day Assessment

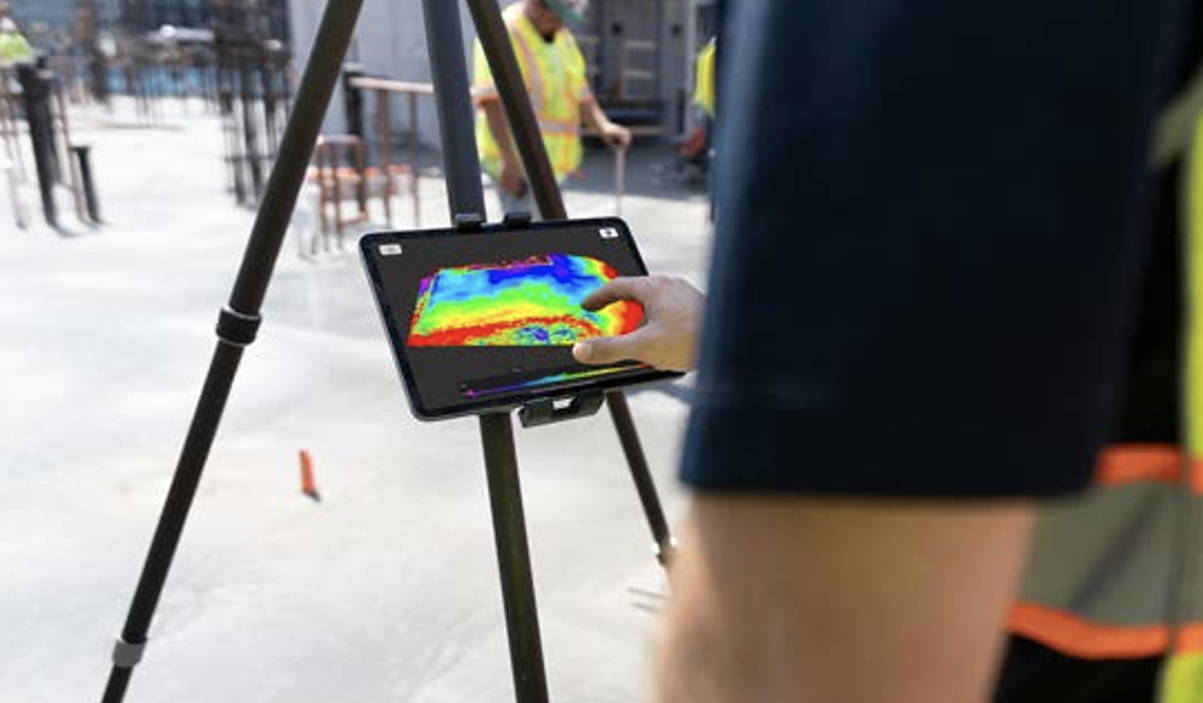

One of the key advantages of the FARO Flatness Check is the ability to perform flatness and levelness analysis on the same day a concrete slab is poured. Unlike traditional methods that require the concrete to cure before evaluation, the Flatness Check App on an iPad connected to a FARO Focus Laser Scanner enables immediate on-site visualization. This feature allows construction teams to ensure that concrete pours are completed on schedule and identify any necessary corrections promptly.

Improved Efficiency

Traditional methods such as dipsticks, straightedge tests, and wheel-based profilers are time-consuming and tedious. Floor analysis using these methods can take up to 48 hours to complete. In contrast, the FARO Flatness Check leverages laser scanning technology to generate a 3D heatmap of the concrete slab in minutes. By utilizing augmented reality (AR) technology, the app can quickly identify areas that are out of tolerance, reducing the analysis time to just an hour. Moreover, laser scanners provide a precise and complete visual representation of the site, minimizing the risk of overlooking potential mistakes compared to traditional measurement data, which is often limited in scope.

Less Rework and Verifiability

The FARO Flatness Check helps reduce rework by providing accurate data that enables the identification of swells and dips in the concrete slab in real time. This allows the finishing crew to patch up any imperfections while the concrete is still workable. For larger slabs, the scan data helps ensure that future rework is done right the first time. Additionally, the 3D-documented results obtained through laser scanning provide a verifiable record of the measurements taken spatially. This allows for independent investigation, data testing, and a higher level of confidence in the accuracy of the results.

How It Works:

1. Pour the concrete

Prepare the job site and ready the concrete while determining the scan positions.

2. Scan the concrete slab:

Set up the FARO Focus Premium Laser Scanner and perform the scan using the Flatness Check App on an iOS tablet. Multiple scans may be needed for larger slabs, but often one scan is sufficient.

3. Compile scan data into 3D model:

Transfer the scans to the app, where they are compiled into a 3D model. The results can be visualized using the iPad's AR capabilities, overlaying the model onto reality.

4. Adjust the workable concrete:

Analyze the scan data to identify swells and dips in the concrete. Direct the finishing crew to address these imperfections while the concrete is still workable. For larger slabs, the data helps ensure future rework is done correctly.

Why Choose Measur?

Measur Geomatics specializes in providing geospatial technology solutions for various industries. Additionally, here are a few ways that we can help:

For industry leading geomatics equipment, contact a member of our team today to find the right equipment for your application.